The international material handling equipment market continues to grow, particularly after the beginning of globalization. Rapid industrialization and developments in technology sectors like the Internet of Things (IoT), Artificial Intelligence (AI), and Radio Frequency Identification (RFID) are further stimulating the boom of the international material handling equipment market.

In addition, the market is projected to reach a whopping $41.18 billion by 2025 , at a CAGR of 6.8%. Many industries such as automotive, agriculture, aerospace, e-commerce, and construction have already begun to understand the importance of material handling systems as well as identify the potential of the upcoming generation of automated materials handling system (AMHS) and equipment.

In this guide, we look at the kinds of material handling systems, how they differ, and talk about the 5 ways a material handling system will boost your revenue.

Introduction to Material Handling Systems

A materials handling system basically involves storing, packing and unpacking, and transporting goods and products across a relatively short distance or in a confined space such as a manufacturing plant or warehouse. There are usually three types of material handling systems: manual, automated, and semi-automated.

Manual Material Handling

Manual material handling (MMH) incorporates the use of physical efforts and force to lift, move, store, and retrieve goods and products. Organizations typically have to depend on animal or human labor for manual handling. Pushing, lifting, lowering, pulling, holding, carrying, or restraining are the most common activities associated with MMH.

Automated Material Handling

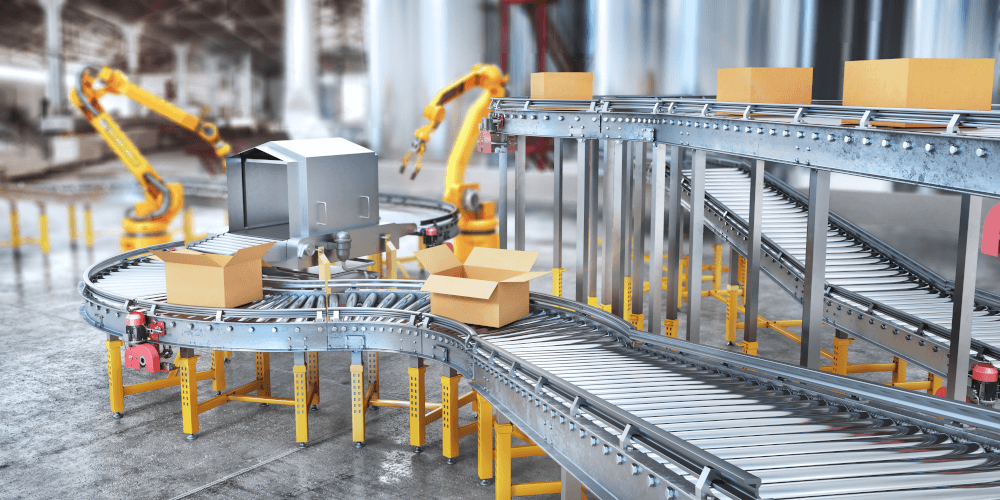

On the other hand, Automated Material Handling (AMH) uses robots and several other automated devices for lifting, moving, pushing, pulling, and storage and retrieval of goods and products.

Automated material handling might involve using either single mechanical equipment or an entire set of different devices like conveyors, sorters, stackers, check-in tools, bins, totes, tote carriers, trolleys, and unloading machines, among many others.

Semi-Automated Material Handling

Semi-automated material handling is a good alternative to full warehouse or manufacturing automation . A semi-automated material handling system enables your operations to maintain more or less the same amount of competitiveness without needing to invest as much money as you would with full automation.

The Fundamental Differences between Manual and Automated Equipment Handling

Manual Equipment Handling

Manual equipment handling is one of the most archetypal materials handling strategies worldwide. In this, operators move around the warehouse or building to store, retrieve, and locate the goods and materials. When compared to automated manual handling systems, manual material handling systems have a relatively slow speed.

A manual system might often lead to inaccuracies or errors since they rely solely on human labor. Moreover, they lack agility and scalability since you cannot program manual systems to handle multiple operations simultaneously.

Manual material handling systems have plenty of obvious limitations in terms of optimizing your storage space. They might also not offer higher productivity and efficiency, which significantly leads to error-prone inventory management and order fulfillment processes. Hence, it’s more appropriate for operations that are not predictable or repetitive.

Since your labor force does not have to operate any state-of-the-art machines, they do not require any technical skills. However, you need to give them safety training. Mishandling or improperly handling heavy loads and workplace injuries, accidents, or deaths resulting from such errors is a principal concern for manual systems.

In manual material handling, you’ll mostly have to depend on your laborers to move, lift, pull, push, and store and retrieve the goods. But sometimes, you might even be required to handle the loading and unloading of goods and products via machines and use lifting handling equipment like:

- Manual cranes

- Trucks

- Slings and hooks

- Forklifts

- Pallet trucks

- Pallet jack

- Short-distance conveyors

- Side-loaders

- Manual retrieval and storage equipment

On the plus side, the startup investment is relatively low, which means manual systems can provide a fast return on your investment. Therefore, they are prevalent amongst small and medium-sized enterprises (SMEs).

However, even though they call for minimal initial investment costs, it is also true that you require a considerable sum of investment in training new employees and have to bear significantly higher labor costs.

Automated Equipment Handling

Automated handling systems use cutting-edge technology to build computerized systems for moving, locating, retrieving, storing, and moving goods. They do not need manual interference. Compared to manual systems, automated systems are relatively more agile, faster, and easily scalable.

You can quickly adapt automated handling systems to perform multiple tasks with adequate and careful planning and research. Moreover, they can be scaled up or down in real-time. Automated systems are the ultimate definition of precision, so there’s practically no chance for them to cause inaccuracies.

Automated systems yield higher efficiency and productivity levels as they depend on computerized machines and not human labor. They aid in optimizing the storage and warehouse space and enable you to make the most use of vertical ceiling clearances. Moreover, they are apt for predictable or repetitive order fulfillment processes.

Also, there are fewer injuries or accidents since there are hardly any chances of errors or improper handling due to repetitive and routine tasks. Some of the best examples of automated handling systems are:

- Conveyor systems

- Automated storage and retrieval systems (AS/RS)

- Automatic guided vehicles

- Mechanized loaders

- Robotic delivery systems

- Pickers

- Bucket elevators

- Lifting equipment

- Grain elevators

Contrary to manual systems, automated ones call for a substantial sum of money as a startup investment. The costs may further escalate if you aim to set up a tailored system. It might take you more than a few years to get your return on investment with automated handling systems.

Thus, most organizations are hesitant to invest such a vast sum of money in automated systems with a payback period of 2 or more years. However, you can compensate for these costs significantly by saving on manual labor, order fulfillment accuracy, and increased productivity.

5 Ways A Materials Handling System Will Boost Your Revenue

The company's material handling processes and systems are put in place precisely to shorten delivery times, reduce inventory, improve customer service, and lower overall handling costs manufacturing, transportation, and distribution. Moreover, here are 5 ways how a materials handling system can boost your revenues.

Save money

Material handling equipment might be costly initially, but they indeed prove to be a significant money saver in the long run. Such equipment helps companies deliver products to their customers more efficiently without adding additional manpower or stretching the budget.

When a company can save heaps of money on these things, it’ll automatically start seeing a boost in its revenues. Minimizing the number of people need to sort, handle, package, and ship items saves money and significantly shortens the time it usually takes to ship packages.

What this indicates is that you can now get the work done faster and better with a lot fewer human workers than with manual equipment. Being a business owner, you can save considerable sums of money by hiring fewer workers at the factory.

Automated manual handling equipment like robotic delivery systems help considerably on route planning and load consolidation, which ultimately helps save on resource expenditures. They are primarily known for speeding up a company’s productivity levels.

Undoubtedly, automated material handling systems is a reasonable investment that truly pays off with time and results in higher revenues and profit.

Improve efficiency and productivity

Staying on top of the competition within the manufacturing sector requires greater efficiency and for logistics and operations. The use of material handling solutions is probably the best way to enhance efficiency and productivity.

It allows workers to focus on one project at a time. Without needing to do everything at once, workers can simply prioritize their tasks accordingly, which improves productivity significantly. This is good news for companies because increased efficiency and productivity are the most significant contributors to increasing your revenue.

Material handling systems can further increase the floor staff’s efficiency via automating labor. These automated systems can increase the unit load by minimizing the number of trips in a warehouse facility. Consequently, workers will be able to accomplish greater work in less time.

Naturally, workers are forced to take care of bulk materials, so they’re bound to experience fatigue which significantly hampers workers’ productivity. Material handling equipment can take most of the burden off the workers’ shoulders, thus increasing productivity.

Moreover, equipment like automated conveyor belts speed up the manufacturing cycle and speed and increase productivity to a great extent.

Better customer service

It goes without saying that offering exemplary customer services is the key to winning your customers and retaining them. Shorter shipping and delivery times ultimately convert to happier customers and more business.

Furthermore, ensuring customers receive timely shipments and the products are undamaged maintains the existing customer base as well as brings in new business. It even increases revenues via referrals of satisfied customers.

By using automated material handling systems, you can fulfill customer orders faster, improve shipping methods, and minimize or practically eliminate all sorts of mistakes. These things meet and sometimes even exceed customers’ expectations, making them super delighted to be a part of your business.

Moreover, the significant increase in productivity with automated systems also enables you to acquire new customers as you tend to fulfill more orders. When customers are happy, they'll be loyal to your brand for life and give you more business in the long run.

Attract employees and improve worker satisfaction

Implementing the ideal material handling systems to keep workers safe drastically helps in attracting good quality workers. This kind of environment also appeals to high-caliber employees with much more training and experience to handle such complex systems, contributing to a better company reputation.

Workers can carry out tasks with confidence since material handling systems ensure control, accuracy, and safety, fostering a positive work environment and a more significant level of worker satisfaction.

Incorporating the use of material handling equipment indicates that workers will be better able to perform their jobs without being concerned that their safety is compromised.

When inventory is kept in the right place at the right time, workers won’t be forced to keep looking for misplaced items. Moreover, they won’t have to deal with faulty or damaged products, which lowers morale and causes frustration.

Automated material handling systems helps them to prioritize their projects and accomplish more work in relatively shorter periods. This promotes their satisfaction levels, productivity and ultimately leads to a boost in revenues.

Better workplace safety

Most employers are quick to state that worker safety is one of their top concerns and priority. However, not all companies mean this or actually take the time to discover which technologies can actually contribute to a safer workplace environment.

The numbers on workplace safety occurrences can speak volumes and ultimately make or break your company's reputation. If your company has a poor reputation due to a high number of workplace accidents or injuries, then you can definitely bid farewell to whatever revenues you’re currently earning.

Think of everything lift trucks and pallet jacks can do for your company. The forklifts can load up to 50,000 lbs, almost two dozen feet above. Trusting drivers is another thing, but you certainly owe it to them to minimize any chances of potential hazards.

Thus, investing in automated material handling systems is the best way to ensure employee safety and ultimately boost your revenues. Companies that wish to increase their bottom line and revenues by reducing the time to complete critical tasks and improving safety can do it by using automated pallet trucks and robots for picking up totes.

Manual vs. Automated Material Handling System: Which is the Best?

Choosing between a manual material handling system and an automated material handling system primarily depends on the volume of your existing and future material handling requirements, and of course, your budget.

Suppose you have low volumes and are unlikely to change considerably anytime soon. In that case, you might just end up investing a massive chunk of capital in an upgrade that’s probably unnecessary for your business.

However, if you decide to integrate automation, you should first try it on a small scale. For instance, you can start by making minor changes to your current manual material handling systems by introducing engineered systems within your production line.

Once you observe the results of this pilot testing phase, you can implement it on a bigger scale. However, the decision to switch to automated material handling systems must be well-informed, based on comprehensive research, as the return on investment (ROI) period will be significantly longer.

Why Companies Are Switching From Manual to Automated Material Handling

Manual handling is losing ground fast as most successful companies come across the efficiency of automated material handling systems. Manual material handling requires the labor workforce to transport objects in a vehicle or a warehouse manually.

Some of the disadvantages of a manual material handling system are that they limit a company’s operational productivity and efficiency and put employees at high risk for accidents and injuries.

Conversely, automated material handling systems limit the physical movements in the order fulfillment process, which signifies that they will minimize additional costs, boost your revenues and production flow, and increase worker safety.

In addition, automated handling enhances all your supply-chain operations by boosting your overall accuracy and profitability, indicating it is a wise investment for your manufacturing or warehouse facility.

Most manufacturing and warehousing facilities are gradually switching from manual to automated material handling systems, and for good reasons. The advantages of automated material handling systems significantly outweigh those of manual material handling systems.

Manufacturing entails numerous steps along with the different stations during the material’s life cycle, which must be transported to each subsequent step. If this is done solely by human efforts, it can be repetitive and monotonous, costly, and result in poor use of labor. An AMHS aims to solve these issues and provide a significant array of benefits, like:

Improved cycle times

The material does not need to wait to be carried by the operations. An automated material handling system owns this responsibility. It frees operators to attend to other important tasks within their assigned areas.

The time it usually takes to transport from one step to another becomes repetitive and predictable over time, which helps improve cycle time estimates and enables you to make more precise due-date estimates for customers.

Reduced contamination

Some manufacturing environments are susceptible to particles in the air that can be easily generated by workers' movements. As a result, they can contaminate the products being manufactured.

Thus, efforts to minimize unnecessary movement can significantly aid particulate-sensitive environments (such as semiconductor manufacturing) in achieving Class 1000, Class 100, or Class 10 certification.

Maximize space

Space within the production floor is essential for ease of movement of products and equipment. Automated materials handling systems such as lifts make it relatively easier to store products and materials. It enables you to stack items high and easily access them, opening up additional storage space and workspace in your plant or warehouse.

Storage and handling equipment like stackable frames can make the most efficient use of space on the production floor as they assist with holding items that aren’t being transported.

Easier location of the material

A true AMHS includes the implementation of material and carrier tracking systems. This is particularly helpful with significant-volume manufacturing.

With the automated systems constantly keeping track of the whereabouts (or the last known location) of a given carrier, material, or part, the AMHSs can be used to find stuff that is missing due to disabled or damaged identifiers.

Increase warehouse value

The resale value of your equipment and warehouse significantly increases with automated material handling systems. Under any circumstances, if you decide to sell your workplace, having automated handling systems in place will undoubtedly attract many buyers.

Moreover, it also means you can quote a significantly higher price for the individual pieces of equipment or the full package.

More effective quality control

In contrast to performing manual quality inspections, automation is much more accurate. Manual inspections are highly prone to human errors primarily because sometimes workers aren’t paying their full attention or any defective product has somehow slipped through the cracks.

Luckily, automated quality inspections use technology to detect errors that reduce rework and product waste.

Final Thoughts

Despite the increasing push for automation in the material handling industry, most companies still continue using conventional manual handling systems. A few manufacturers and warehouses have even managed to find the perfect equilibrium between manual and automated systems as the proper solution for their company.

Nonetheless, it’s quite evident that automated material handling systems come with a vast array of benefits. Automated systems are ideal for organizations that look forward to making their processes faster, easier, and safer.

Hence, if you want to take your operations and procedures to the next level, switching to an automated material handling system from a manual one is a surefire way to do it.