The transition from Gears, Chains, and Belts

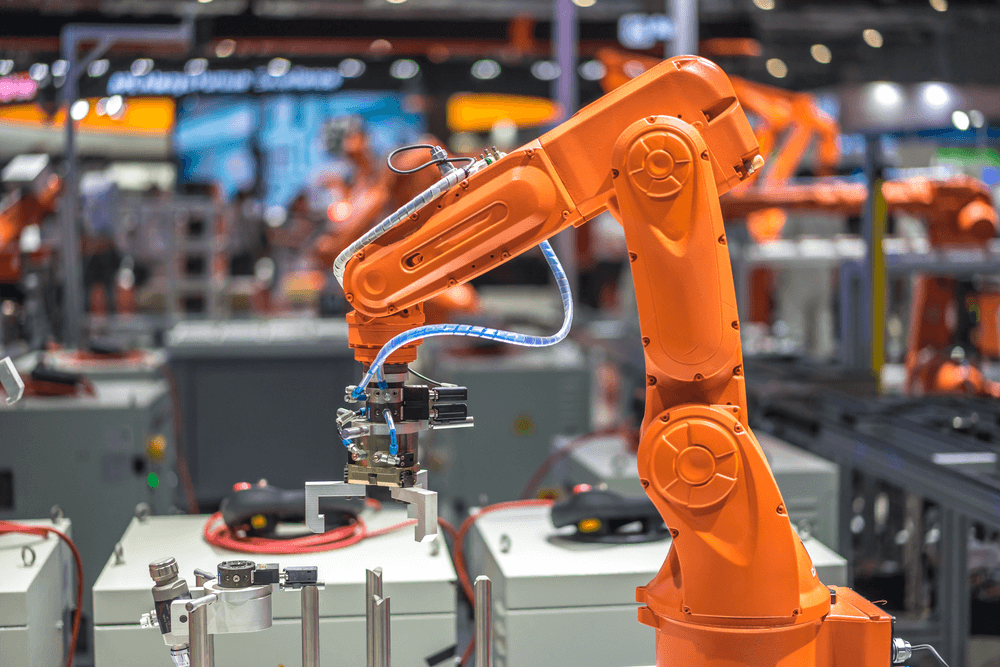

However, when it comes to more extensive systems, robotic technology is as efficient as the conveyor systems on which the convenience goods are assembled and transported. Even though our automation services are not limited to providing efficient conveyor systems, the convenience consumer product industry benefits phenomenally, especially post-pandemic, from revolutionary conveyor systems that improve throughput and flexibility.

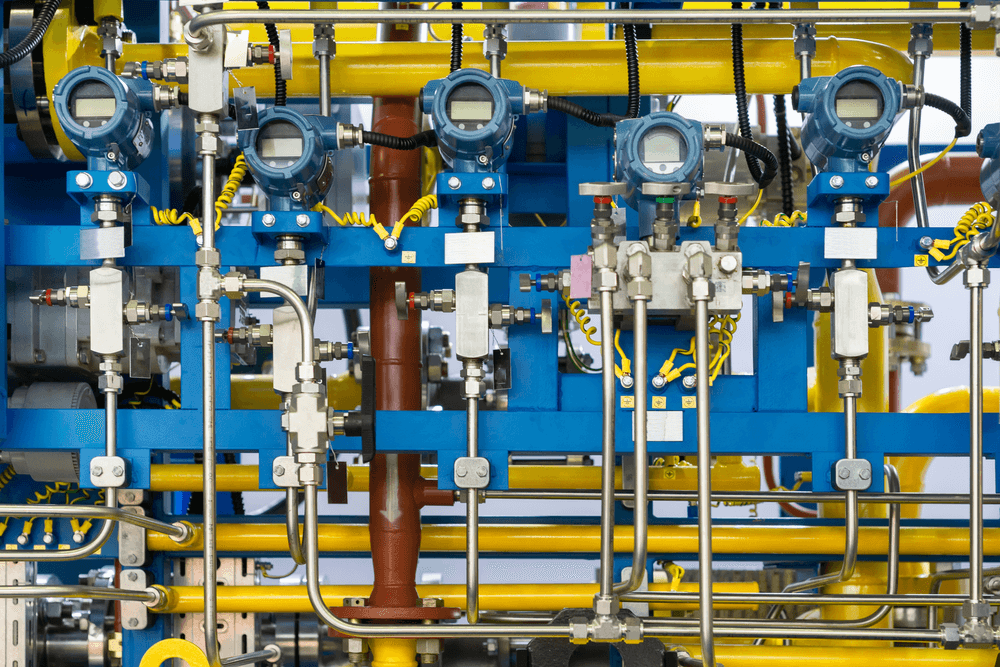

During the immediate lockdown, companies with modern automated manufacturing units overcame the setback and upscaled or switched their production SKUs or models to focus on manufacturing necessities. The primary limitation that organizations experience in conventional conveyor systems is the ‘pitch’ – the distance between the movers. These complex designs comprise chains, belts, rollers, gears, and wear components with a high chance of unscheduled downtime.

In contrast, what happens when you switch your product SKUs or move products from one facility to another with an independent cart conveyor? Coupled with analytics, simulations, and leading-edge technologies to increase transparency, maximize uptime, reduce bottlenecks, and digital twin simulations all work together to significantly improve the time-to-market of any manufacturing business decision.