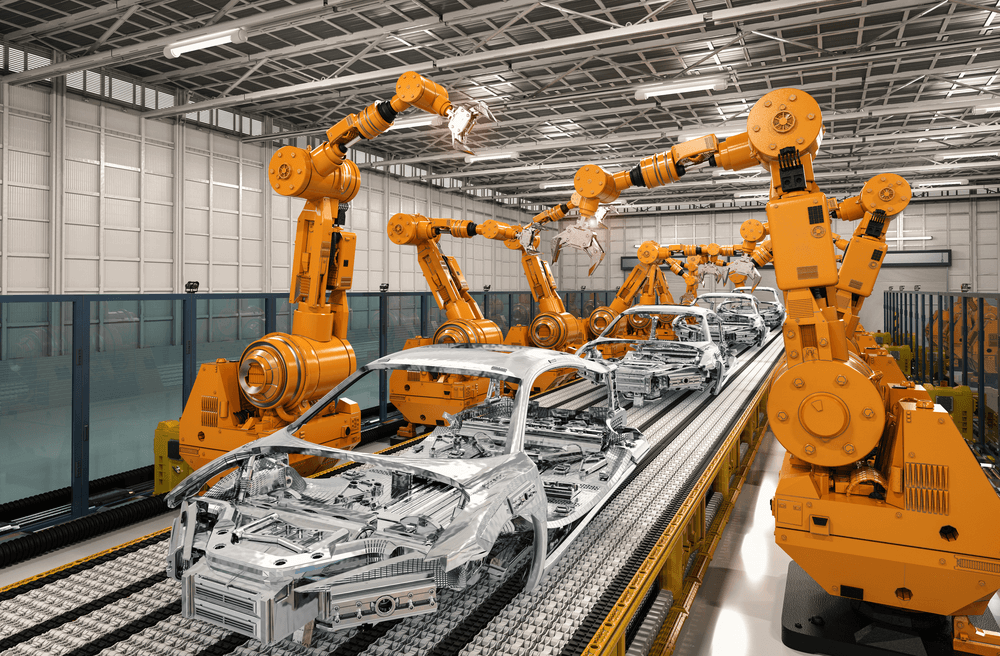

Cavity Waxing to Sealing — Holistic Automation in 'Painting'

Painting in the automotive industry is not just limited to a single process. It involves under-body coating (UBC), seam sealing, cosmetic sealing, rocker panel coating, cavity wax, and exterior and interior painting. Precise-controlled automation UBC stations decrease operating costs and optimize quality with airless processes that enhance anti-chipping, reduce material consumption, and create a safer working environment.

Similarly, automated Liquid Applied Sound Damping (LASD) applies water-based damping material that replaces manual soundproof pads with gapless sealing. High-performance robots can service all types of vehicles through an integrated cutting-edge vision system that provides precise vehicle positioning through double-rectification and then utilizes high-precision customized nozzles for sealing different areas.

Automated Cavity Waxing offers extreme precision with flow control, even spreading along the cavity, and, like cosmetic sealing, the customized nozzles adapt to target holes with different areas. Hydraulic robots are no long appropriate for interior and exterior painting processes. Modern modular painting robots and atomizers achieve better quality and appearance standards with high acceleration and TCP velocity, low maintenance, and compact booth dimensions. The precision that is provided by robotics also ensures that quality and versatility do not need to come at the expense of environmental safety. Overspray-free technologies utilize precise inkjet heads to spray directly onto the targets with 100 percent transfer efficiency. Whether your model requires two-tone paints or individual designs, it is completed in a single pass without masking. Robotics provided by B2E Automation can improve productivity, reduce downtime, and allow for more customizable paint schemes.