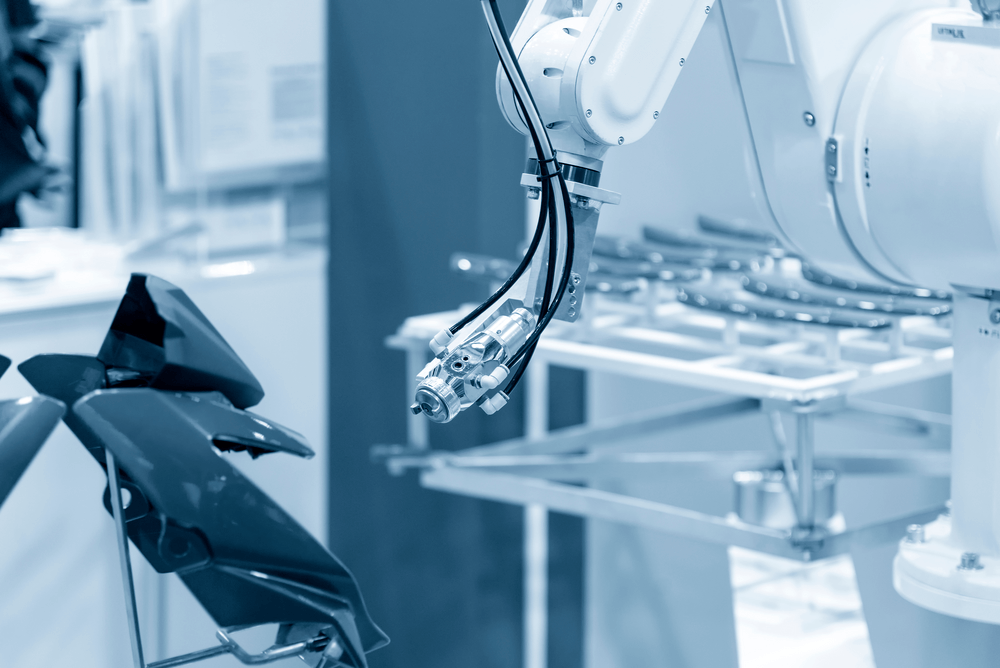

How Do the Robotic Painting Systems Benefit You?

Workplace safety and compliance are no longer concerns with automated painting systems. The transformational painting and coating system preserves human health and boosts production, accuracy, and throughput in the entire value chain.

In addition, companies benefit from:

- Eliminating expensive labor hours, the cost of human error, raw material wastage from over-spraying, and lost production or returns from quality issues.

- A flawless finish produced by even, dripless applications that are free from imperfections.

- Better floor space utilization. As robotic arms are maneuverable, floor managers need not worry about floor space issues. This mobility allows modern painting robots to reach farther than their predecessors.

- Ridding their workspace of carcinogens, Volatile Organic Compounds (VOCs), and iso-cyanides.

- Eliminating double-cycle time with two-tone paint and enabling high-resolution, complicated image paint for smaller requirements.

- Customized solutions that are developed through a group of automated solutions working in close proximity and improving long-term productivity.