Consumer electronics, appliances, semiconductors, pharmaceuticals, automotive, and other industries are the key drivers for the growing robotic part feeding system market. The market is forecast to grow $156.06 million from 2021 to 2025 while accelerating the market’s growth momentum at a CAGR of 7.61 percent. This growth is due to the development of industrial robots with self-diagnostic capabilities that help with predictive maintenance.

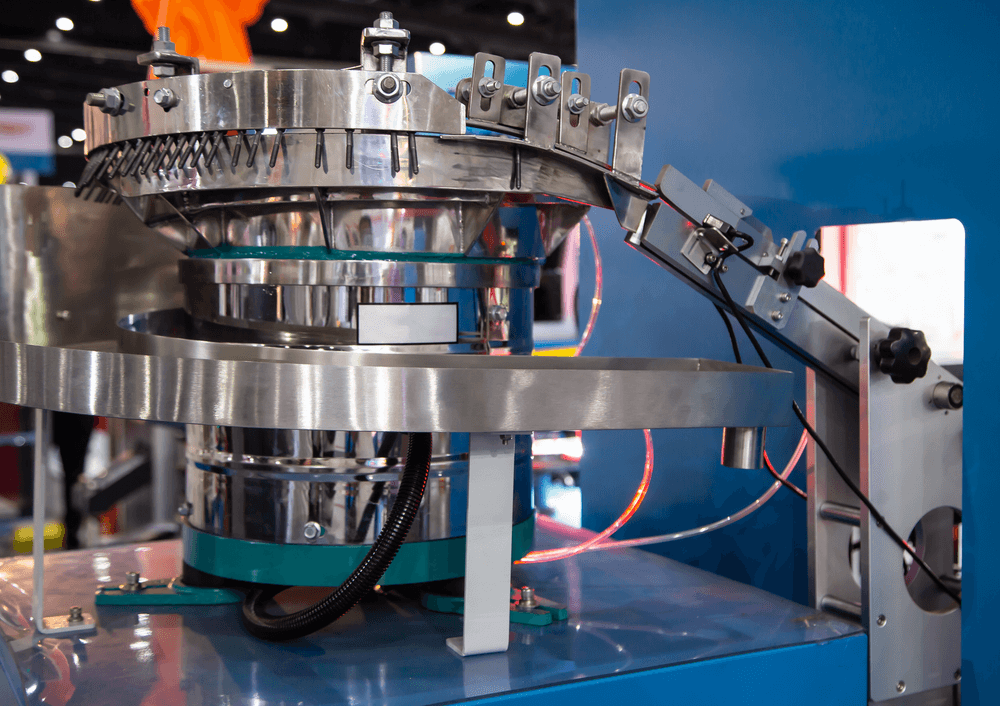

B2E Automation works with manufacturing enterprises to develop, produce, and market high-performing flexible feeding systems for components that range from 0.1 mm to 150 mm. Oriented towards your business vision, we focus on easy integration with your current systems, resulting in optimized production speed, accuracy, and flexibility. Our highly effective results are obtained through our key competencies and knowledge of all sub-domains of modern part feeding systems – from vibration technology to precision robots to vision-guided robots and feeding bowls.

Our designs are compatible with all parts variants, whether the unit must handle complex geometries or highly delicate parts. We help you gain a competitive advantage and a shorter return on the investment cycle.