Which Processes Required Automated Dispensing Solutions?

Regardless of the products or processes, virtually all industries require automated dispensing solutions:

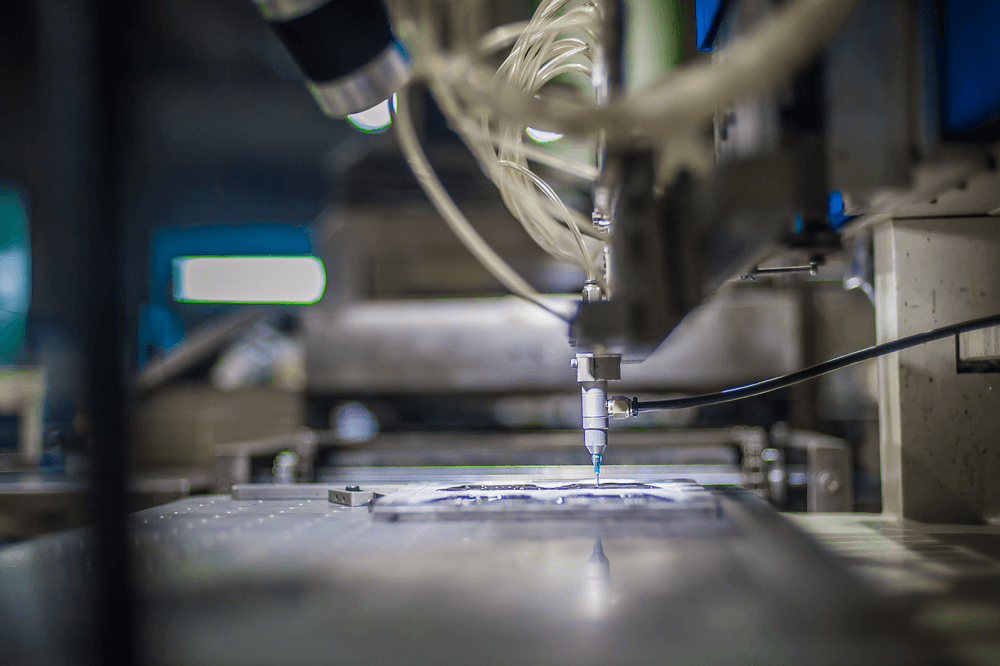

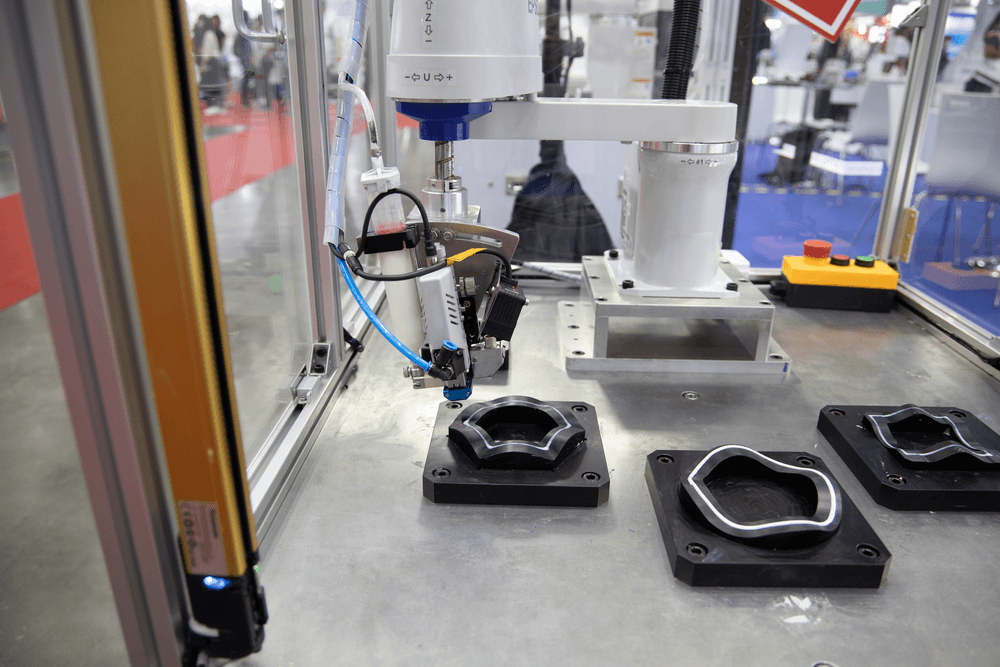

- Automotive industry (loud-speaker bonding, urethane beading, Li-battery cell bonding, dashboard bonding, harness potting and sealing, or sensors)

- Telecommunications industry (loud-speaker, frame, volume-button, circuit-board underfill, or camera bonding)

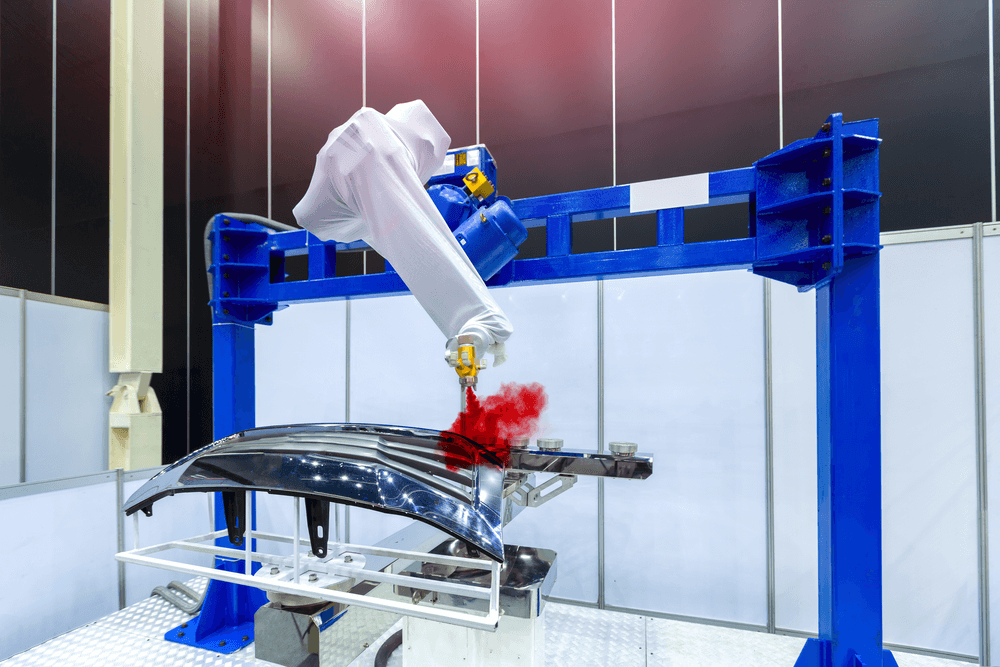

- Aerospace and Defense industry (adhesives, bonding, spray coating, and sealing)

- Energy Extraction and Storage industry (adhesive dispensing, end-of-line battery assembly)

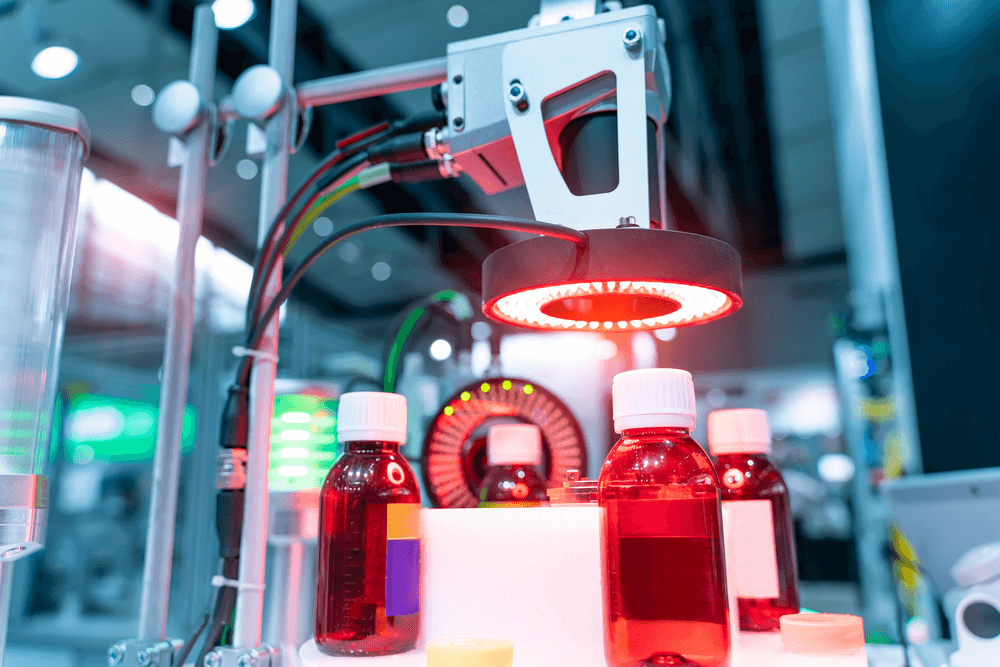

- Consumer Products (lot traceability, swirling, inline bead inspection, product packaging)

- Life Sciences (pipetting systems, media addition and removal without disturbing cell structures, washing equipment, and other virtually unlimited applications)

With a few examples from each industry quoted above, our aim is to build a comprehensive material delivery portfolio that does not shy away from variations in the industry.