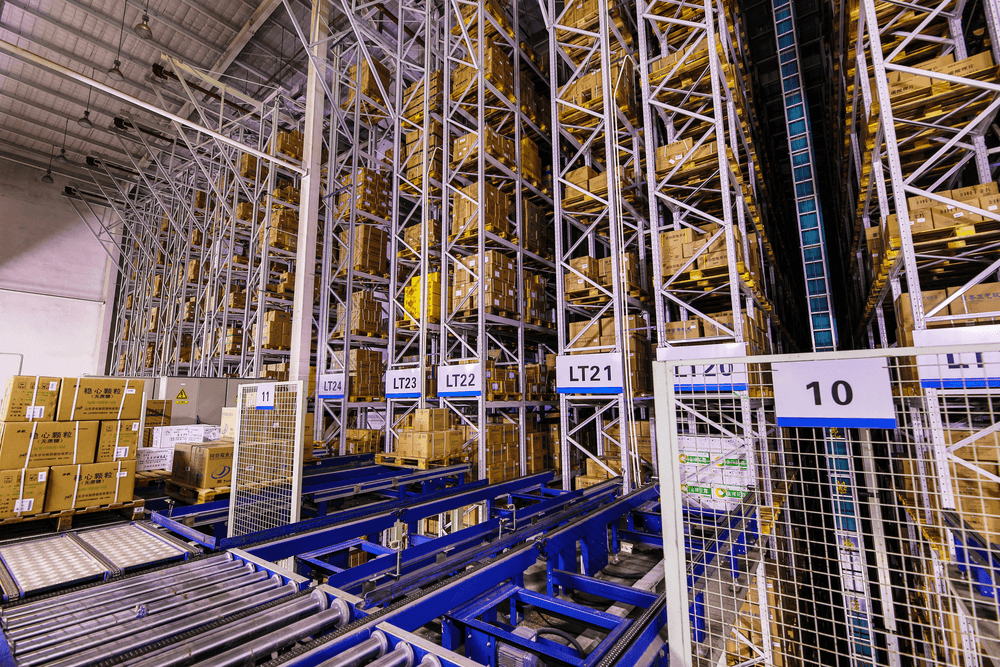

An Automated Storage and Retrieval System (AS/RS) is a system that combines multiple pieces of computer-controlled equipment and control systems to store and retrieve materials for workers. Depending on their applications, these systems can vary widely in their size and in their level of automation.

AS/RS systems first appeared in the 1960s and originally focused on heavy pallet loads. However, as the technology in AS/RS systems has progressed, these systems have been able to assist with smaller and smaller loads and in greater varieties of scenarios. The engines of AS/RS systems are their specialized computers, which maintain information on item types, quantities, and locations. Storage and retrieval machines (SRM) are then sent to these locations to fetch the items and deliver them to manufacturing floors or loading docks.